SIMECO and SIMECO-2: Simulation of In-vessel MElt COolability

The SIMECO experimental facility is devoted to the study of heat transfer in 2- and 3-layered stratified molten pool formed by oxide and metal simulants with different densities covering the following key phenomena:

(i) relocation (inversion) of oxide and metal layers driven by the change of melt densities

(ii) effect of the crust formation on the top/bottom layer interfaces

(iii) influence of top metallic layer thickness on the focusing effect

(iv) multidimensional heat transfer partitioning between, the melt pool, the top metallic layer and the vessel.

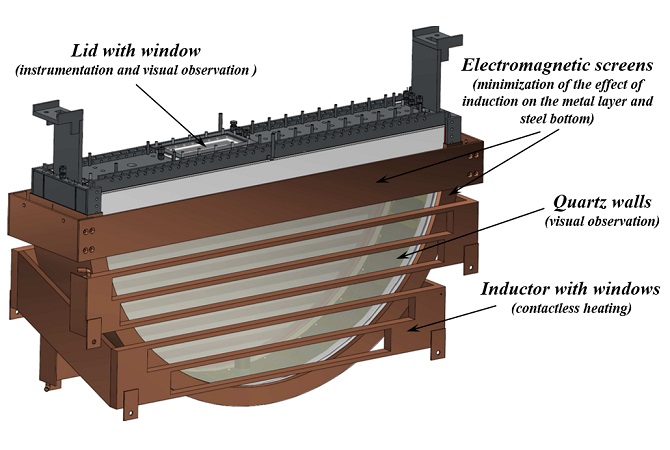

The new SIMECO-II test section is a slice-type vessel, which includes a semi-circular section, representing the lower head of the reactor vessel. The diameter, height, and width of the working volume of pool are 1000x500x120 mm, respectively. The following important features of SIMECO-II design can be noted: (i) optically transparent front and back walls made of quartz, that allows a visual observation of pool behavior, such as crust growing and to measure velocities of local and global heat flows; and (ii) contactless induction heating of melt which exclude hydrodynamic resistance of heaters installed in the pool and interaction of the melt with the heater materials.

Schematic of the SIMECO-2 test section

The original SIMECO experimental facility consists of a slice type vessel, which includes a semi-circular section and a vertical section, representing the lower head of the reactor vessel. The size of the facility is scaled to be 1/8 of prototype PWR type reactors. The vessel’s sidewall is represented by a thick brass plate, which is externally cooled by a regulated water loop. On the top of the vessel a heat exchanger with regulated water loops is employed to measure the upward heat transfer. The sideways and upward heat fluxes are measured by employing array of thermocouples at several different angular positions. Cable type heater with 3 mm in diameter and 4 m in length provides internal heating in the pool. Practically isothermal boundary conditions are provided at vessel boundaries with help of isothermal bath. A plate type heat exchanger mounted in the isothermal bath circuit to increase cooling capacity of isothermal bath. The cooling circuit has two parallel paths, one for sidewall heat exchange and other for top heat exchange. Top heat exchanger flow is established by isothermal bath inbuilt recirculation pump. Second external recirculation pump was mounted in order to establish necessary flow rate for sidewall heat exchange. A digital flowmeter measures sidewall flow and an analog flowmeter measures top heat exchanger flow.

The diameter and height of the test section are respectively 62.0 cm and 53.0 cm. The width of a slice is 9.0 cm. The front and back faces of the facility are insulated in order to decrease heat losses. Thickness of the vessel wall is 2.3 cm.

A total of 64 K-type thermocouples are mounted to obtain data on sidewall heat flux, heat flux on top of pool, inlet and outlet water temperatures, as well as pool temperatures inside the vessel, and the upper heat exchanger.

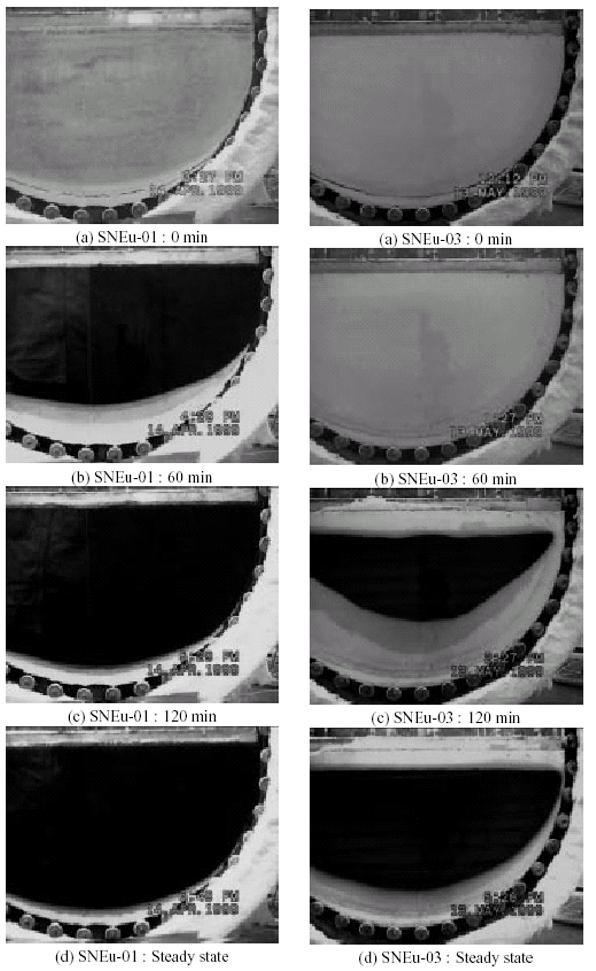

The visual observation of the pool melting in the old SIMECO experiments